A diamond band saw uses a blade that is similar to the sort of blade that you would find on a traditional wood cutting band saw, except that has a diamond coating instead of teeth. One advantage of a band saw is that it has a very thin blade, so that it removes only a small amount of glass as it cuts. This translates into faster cutting, since the saw is doing less work. The thin cuts are also an advantage when doing certain types of projects such as lamps or windows that will be foiled because the blade is only removing a thickness equivalent to about two pieces of foil. This can reduce the amount of cutting required by one-half in certain projects (see explanation in the videos or in the lampmaking instructions). The band saw also has the advantage of being able to cut much thicker pieces of glass or other hard material. The band saw will accept a slab up to about 3” in height, whereas the wire saw and ring saw are limited to about 3/8”. The band saw is a much more satisfactory choice for thick glass (including fused glass) and lapidary.

A round-bladed saw such as the wire saw or a ring saw allows the operator to cut in any direction, which may be more intuitive for some people. Because the wire or ring blade is thicker than the band saw blade, the blade removes more material with each cut than a band saw. A wire saw, since it has a straight blade, can also make inside cuts by first drilling a pilot hole in the glass. A band saw would require a lead-in cut in order to cut that same pattern.

With regard to expense of operation, the Omni-2 wire saw is by far the least expensive of the saws due to the small, inexpensive blades and simple construction. There is very little maintenance required. The ring saw, by contrast, requires frequent replacement of moving parts. The C-40 band saw is relatively low-maintenance, but the blades are more expensive than those for the wire saw.

Any of these saws will be able to make exactly the same cuts (with the exception of inside cuts), so the choice ultimately rests on the factors stated above.

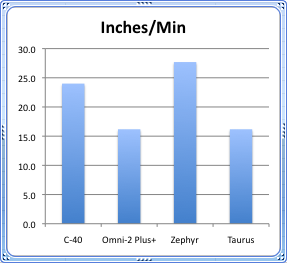

The chart below illustrates the relative speed of cutting of the various saws. Each saw was tested using the same piece of ripple art glass, and the same total length of glass was cut with each saw. Each saw was fitted with a brand new blade for the test. Keep in mind that the type and thickness of material cut as well as the wear of the blade will effect the cutting speed, so your experience may differ. The test does accurately reflect the relative cutting speed of each saw, and is a useful component of your decision making process.

A round-bladed saw such as the wire saw or a ring saw allows the operator to cut in any direction, which may be more intuitive for some people. Because the wire or ring blade is thicker than the band saw blade, the blade removes more material with each cut than a band saw. A wire saw, since it has a straight blade, can also make inside cuts by first drilling a pilot hole in the glass. A band saw would require a lead-in cut in order to cut that same pattern.

With regard to expense of operation, the Omni-2 wire saw is by far the least expensive of the saws due to the small, inexpensive blades and simple construction. There is very little maintenance required. The ring saw, by contrast, requires frequent replacement of moving parts. The C-40 band saw is relatively low-maintenance, but the blades are more expensive than those for the wire saw.

Any of these saws will be able to make exactly the same cuts (with the exception of inside cuts), so the choice ultimately rests on the factors stated above.

The chart below illustrates the relative speed of cutting of the various saws. Each saw was tested using the same piece of ripple art glass, and the same total length of glass was cut with each saw. Each saw was fitted with a brand new blade for the test. Keep in mind that the type and thickness of material cut as well as the wear of the blade will effect the cutting speed, so your experience may differ. The test does accurately reflect the relative cutting speed of each saw, and is a useful component of your decision making process.